Cartridge Heaters

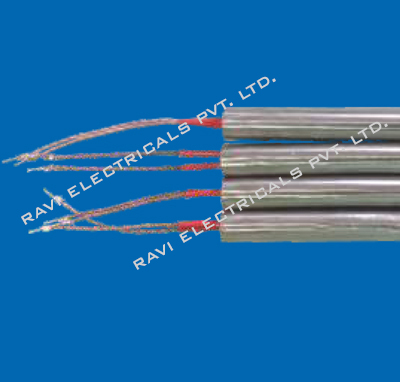

Ravi Electrical is a manufacturers, exporters, & suppliers of cartridge heater in Mumbai, India. A cartridge heater is an industrial heating element that is tube-shaped and can be installed into drilled holes. They provide localized and accurate heating and are widely used in heating process industries. Cartridge heating elements are typically used to heat an internal metal block and can be customized to a particular watt density depending on the application. The most common use of cartridge heaters is to heat metal parts by inserting them into drilled holes. These heaters are designed to be slightly smaller than their nominal diameter for easy installation.

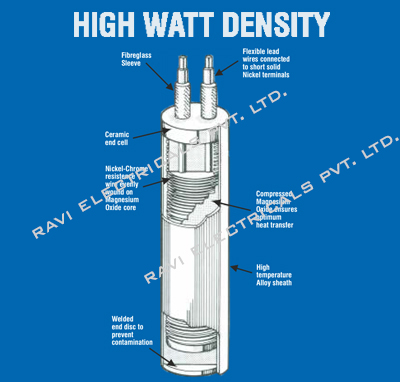

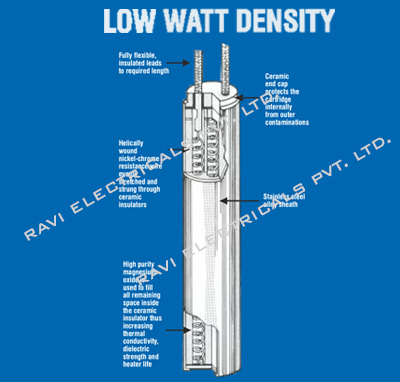

Ravi Electricals Pvt Ltd offer High Watt Thickness Cartridge Heaters in SS 304 & SS 316 watt density of 12 watt/sq.cm & less watt density cartridge heaters in brass or SS 304 sheath with watt density of 4 watt/sq.cm. Even they are available with in-built Thermocouple as per requirement. Different type of Terminations available & offered on request. Heaters are designed for giving max performance & longer durability.

Ordering Information:

- Diameter

- Length

- Wattage

- Voltage

- Wire lead length

- Inbuilt Thermocouple required or not

- Termination type

Application

- Cartridge heaters can be specified to meet the demand of special Application:

- Moulds & Dies

- Labeling Machines

- Packaging Equipment

- Laminating Equipment

- Heating liquids & gases

Advantages of ceramic band heaters

A cartridge heater is made up of a resistance coil wrapped around a ceramic core surrounded by dielectric, encased in an encased metal sheath. When powered heat is transferred through the coil into the sheath, the sheath heats up. Then, the heat is transferred to the inner metal part that requires heat.

For a cartridge heater to be able to be installed in a low to medium temperature application (600°F and below), most general purpose drills are sufficient for drilling holes. Holes can be drilled between.003” and.008” larger than the nominal hole size of the drill. This will result in fits of.009” to.014”, which is a slightly looser fit than would allow for optimal heat transfer. This helps in installation and removal, especially for long sheath cartridge heaters at high watt densities. The holes should be reamed instead of just drilled with the general purpose bit. A tighter fit will result in a cooler heater and a longer life expectancy.