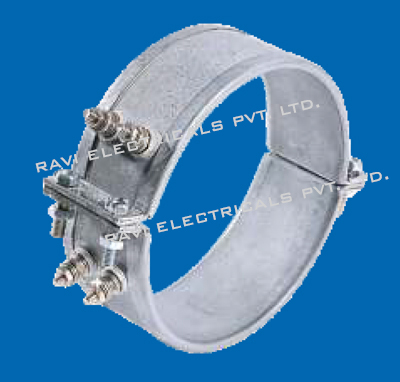

Mica Band Heaters

Mica Band Heaters are offered in a variety of sizes and are available from Ravi Electricals Pvt Ltd. We are a manufacturers, exporters, & suppliers of Mica Band Heaters in Mumbai, India. They are flexible, cost-effective, and dependable. It might be insulated to save up to 10% on energy costs. The raw materials utilised in production are of the highest quality. It makes easy installation with built in Clamping accessories. It can be box-partitioned rounded, or flat.

In every type of plastic dispensation machinery, mica band heaters are often used for heating the moulds, dyes, nozzles, and mainly cylinders (barrels). Mica heaters are most cost-effective.

Max Temperature of case is 300 ° C. 25 watts per square inch is the max wattage thickness. Integrated insulation is accurately engineered for improved heat-reflecting and routine characteristics.

The utmost common square, rectangular and hex-shaped mica heaters can be mass-produced as per buyers specifications in 1 or 2 units. Offered with leads or terminals. Ravi Electricals Pvt Ltd exclusive technique of designing, maximizes the element wire coverage of the heated part. This outcomes in unchanging heat distribution & lengthier heater life.

Construction

- Mica insulation is used to provide insulation as well as moisture resistance.

- Nickel-Chromium Resistance Stripes must be properly wounded for consistent heat distribution and dependability.

- SS or aluminium sheath to boost thermal conductivity and high-temperature oxidation/corrosion resistance.

- A terminal box that prevents spills and protects exposed terminals

- Screw terminals made of stainless steel that have a strong connection to the winding as well as maximum amperage carrying capacity.

- The clamping band is designed to maintain clamping pressure and solid contact with the cylinder's surface, thereby removing air gaps at the connection.

How Do Mica Band Heater Work?

These heaters work on the basis of the conduction or convection mechanism. The mica core serves as insulation for the heating element, which is enclosed in a metal sheath. For even heat distribution, a nickel-chromium resistance strip coiled exactly on a dielectric substance is utilized as a heating element. The heating band will utilize a controlled process to transfer heat to another object after supplying power. Then, this practical heat energy is transferred to the required location using conduction or convection heating technology.