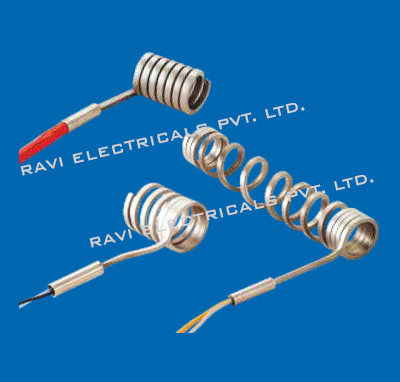

Micro Tubular Heaters

Ravi Electrical is a manufacturers, exporters, & suppliers of micro tubular heater in Mumbai, India. A micro tubular heater is a form of heating element made out of a small, thin tube wrapped with heating wire. The tube is after that insulated and sealed. Micro tubular heaters are utilized in a wide range of applications that need precise temperature control and/or small size.

Conduction is the basic operating principle of a micro tubular heater. Heat is produced by the heating wire inside the tube and then transferred to the surroundings through the tube walls. Temperature differences between the heating wire and the surrounding medium and the thermal conductivity of the tube material affect how quickly heat is transferred.

Ravi Electricals Pvt Ltd offers Micro Tubular Heaters which are adapted to a variety of applications. This is because of its capacity to be modified into any shape. Micro Tubular Heaters are swaged and compressed with magnesium oxide and a helical or straight resistance element. In tight spaces these heaters are used. Inbuilt thermocouples, such as J or K are also available. Circular and square sheaths are also available.

Features

- 360° heated area

- Readily conforms to surface

- Fast response and quick heat transfer

- Helical Coil design for superior performance

- Resistance to corrosion

- Available with thermocouple

Stainless steel, nickel, or copper are all materials that can be used to make micro tubular heaters. The material used depends on the application. For instance, stainless steel heaters are often used for corrosion resistant applications, while copper heaters are used for applications that require high heat conductivity. The power output is determined by the tube length and diameter, heating wire type, and voltage applied to the heaters. Typical power outputs range from a few watts to several hundred watts.

Application

Micro tubular heaters are used in a variety of applications, including:- Hot runner systems in injection molding machines.

- systems for controlling temperature in medical equipment.

- Heating components for laboratory equipment.

- Temperature control systems are used in industrial processes.

- Space heaters